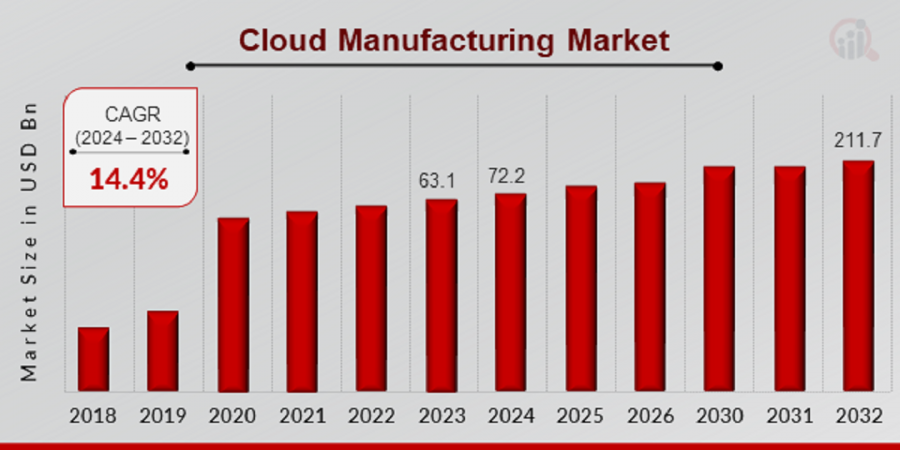

Cloud Manufacturing Market to Reach USD 211.7 Billion by 2032 | Driving the Future of Scalable and Smart Production

Cloud Manufacturing Market is revolutionizing digital production through scalable, cost-efficient, and intelligent manufacturing solutions across industries.

NEW YORK, NY, UNITED STATES, April 22, 2025 /EINPresswire.com/ -- According to a new report published by Market Research Future, The Cloud Manufacturing Market was valued at USD 72.2 Billion in 2024, and is estimated to reach USD 211.7 Billion by 2032, growing at a CAGR of 14.4% from 2024 to 2032.

The cloud manufacturing market is rapidly emerging as a game-changing force in the industrial landscape, blending the power of cloud computing with advanced manufacturing processes. It transforms traditional production systems into interconnected, service-based operations, enabling manufacturers to access shared resources, applications, and capabilities over the internet. With the growing demand for agility, real-time collaboration, and cost optimization, cloud manufacturing is reshaping how factories function, reducing dependence on physical infrastructure, and promoting digital integration across the entire supply chain. As businesses strive for increased operational efficiency, this technology enables flexible production, instant scalability, and seamless innovation through smart data-driven decision-making.

Download Sample Report (Get Full Insights in PDF - 191 Pages) at -

https://www.marketresearchfuture.com/sample_request/6004

As industries embrace digital transformation, cloud manufacturing plays a pivotal role in accelerating the journey toward smart factories. These environments utilize cloud infrastructure to integrate IoT devices, artificial intelligence, and big data analytics into manufacturing workflows. The result is real-time visibility into production lines, predictive maintenance, and more informed resource allocation. Cloud-based platforms enable centralized control and monitoring, ensuring consistency and high-quality output across multiple production sites. This evolution aligns closely with Industry 4.0 goals, providing manufacturers with tools to stay competitive and agile in a fast-changing global market. Cloud manufacturing reduces downtime and supports rapid innovation cycles, which are critical to modern industrial success.

Cloud manufacturing is gaining traction across diverse sectors, including automotive, aerospace, electronics, healthcare, and consumer goods. In automotive, it supports agile design processes and complex component manufacturing. Aerospace companies leverage cloud platforms to enhance collaboration across international teams and suppliers. The healthcare sector benefits from improved traceability, regulatory compliance, and the ability to quickly respond to changing demand. In electronics and consumer goods, cloud-based systems enable mass customization, reduced lead times, and adaptive manufacturing. This wide adoption reflects the market's versatility and its ability to address industry-specific challenges while driving innovation and product quality enhancements.

The advantages of cloud manufacturing are contributing significantly to its market expansion. It offers cost savings by reducing the need for physical IT infrastructure and on-site data storage. Manufacturers can scale operations without major capital investment, tapping into computing resources on-demand. Enhanced flexibility allows companies to respond quickly to market changes or customer demands. Moreover, cloud-based platforms enable global collaboration, connecting teams across geographies and time zones. This interconnectedness facilitates faster decision-making, streamlined supply chains, and improved customer service. With increasing competition and shorter product life cycles, cloud manufacturing provides a competitive edge through improved responsiveness, efficiency, and innovation.

Cloud manufacturing can be implemented through various models depending on organizational needs. These include public, private, and hybrid cloud solutions. Public cloud offers broad accessibility and scalability, often used by small to medium-sized enterprises due to its cost-effectiveness. Private cloud environments provide enhanced control, security, and customization, making them ideal for large enterprises with specific compliance needs. Hybrid models combine the strengths of both, enabling data-sensitive processes to remain in a secure private cloud while leveraging the public cloud for scalability and non-critical tasks. Additionally, Manufacturing-as-a-Service (MaaS) allows companies to outsource specific production functions, paying only for what they use. These models collectively empower businesses to select solutions tailored to their operational priorities and growth objectives.

Buy Now Premium Research Report -

https://www.marketresearchfuture.com/checkout?currency=one_user-USD&report_id=6004

The evolution of cloud technologies is fueling the cloud manufacturing market, with continuous innovations enhancing platform capabilities. Integration with emerging technologies such as AI, machine learning, and edge computing is enabling smarter, autonomous production systems. AI algorithms optimize scheduling, detect anomalies, and recommend process improvements, while machine learning models enhance predictive maintenance and quality control. Edge computing complements cloud infrastructure by processing data closer to the source, reducing latency and ensuring real-time responsiveness. The combination of these technologies empowers manufacturers to create intelligent, adaptive systems capable of evolving with market trends and internal operational insights.

Data security and robust management are critical elements in cloud manufacturing. With the increasing reliance on cloud platforms, manufacturers must safeguard sensitive design files, intellectual property, and customer data. Modern cloud solutions employ advanced encryption, multi-factor authentication, and stringent access controls to protect information. In addition, real-time data backups and disaster recovery systems ensure business continuity and minimize the risk of data loss. Data governance frameworks help maintain regulatory compliance and enhance transparency across operations. As trust in cloud security grows, more manufacturers are embracing the shift to digital infrastructure, recognizing that comprehensive data protection is achievable without compromising flexibility or performance.

Cloud manufacturing contributes significantly to environmental sustainability. By optimizing resource utilization and minimizing waste, it helps reduce the environmental footprint of production processes. Real-time monitoring allows for better energy management and supports the adoption of cleaner, greener manufacturing practices. The ability to produce on-demand and closer to the point of consumption also reduces logistics-related emissions. Cloud-based systems encourage circular economy principles through improved product lifecycle tracking and resource reuse. As environmental regulations become more stringent and consumer demand for eco-friendly products grows, cloud manufacturing offers a viable path for companies to meet sustainability goals while maintaining economic viability.

The adoption of cloud manufacturing is reshaping workforce dynamics, necessitating new skills and competencies. As manual processes give way to digital systems, employees must become proficient in data analytics, software operation, and digital collaboration tools. This shift is prompting a growing focus on reskilling and upskilling initiatives across industries. Manufacturers are investing in training programs, digital literacy, and cross-functional capabilities to build a future-ready workforce. Remote access to cloud platforms also supports flexible work environments, enabling engineers, designers, and technicians to contribute from any location. This transformation not only enhances operational efficiency but also creates new career opportunities in the digital manufacturing space.

Browse In-depth Market Research Report (191 Pages, Charts, Tables, Figures) Cloud Manufacturing Market –

https://www.marketresearchfuture.com/reports/cloud-manufacturing-market-6004

A robust ecosystem of technology providers, software developers, and manufacturing enterprises is driving the cloud manufacturing market forward. Cloud service providers offer infrastructure and platform support, while software vendors deliver specialized tools for product design, quality assurance, and supply chain management. Collaborations among these stakeholders foster innovation, interoperability, and integration across systems. Open-source platforms and standardized APIs are facilitating smoother connectivity between different solutions. Strategic partnerships also accelerate digital transformation by providing companies with access to the latest technologies without long development cycles. This interconnected ecosystem ensures that cloud manufacturing continues to evolve, offering ever-more sophisticated solutions to meet dynamic industrial needs.

Despite its many advantages, cloud manufacturing faces challenges that must be addressed for widespread adoption. Concerns around data privacy, integration complexity, and resistance to change in traditional manufacturing settings can slow down implementation. Additionally, issues related to network latency, compatibility with legacy systems, and regulatory compliance may pose hurdles. However, as technology matures and awareness grows, these challenges are expected to diminish. The future outlook for cloud manufacturing is promising, with increasing investments in digital infrastructure and a growing emphasis on resilience, sustainability, and agility. Emerging markets are also showing strong interest in cloud-enabled production systems, indicating a global shift toward smarter, connected manufacturing.

The cloud manufacturing market represents a transformative shift in the way products are designed, produced, and delivered. By leveraging cloud technologies, manufacturers can achieve greater scalability, operational efficiency, and innovation. From enabling real-time collaboration to supporting sustainable practices and workforce modernization, cloud manufacturing is at the heart of the next industrial revolution. As digital maturity increases across industries, the demand for cloud-based manufacturing solutions will continue to grow, shaping a future where intelligent, responsive, and customer-centric production is the norm. Businesses that embrace this evolution are well-positioned to thrive in an increasingly competitive and digital-first world.

Top Trending Reports -

Mobile Money Market -

https://www.marketresearchfuture.com/reports/mobile-money-market-1052

Railway Cybersecurity Market -

https://www.marketresearchfuture.com/reports/railway-cybersecurity-market-10707

IDaaS Market-

https://www.marketresearchfuture.com/reports/idaas-market-11086

Industrial IoT Platform Market -

https://www.marketresearchfuture.com/reports/industrial-iot-platform-market-2186

IOT Operating Systems Market -

https://www.marketresearchfuture.com/reports/iot-operating-systems-market-5924

Web Filtering Market -

https://www.marketresearchfuture.com/reports/web-filtering-market-5962

WLAN Market -

https://www.marketresearchfuture.com/reports/wlan-market-1012

Cloud Workload Protection Market -

https://www.marketresearchfuture.com/reports/cloud-workload-protection-market-8116

Carrier Wi-Fi Equipment Market -

https://www.marketresearchfuture.com/reports/carrier-wi-fi-equipment-market-5312

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

Contact:

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: sales@marketresearchfuture.com

Website: https://www.marketresearchfuture.com

Sagar Kadam

Market Research Future

+1 628-258-0071

email us here

Visit us on social media:

Facebook

X

LinkedIn

Distribution channels: Technology

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release