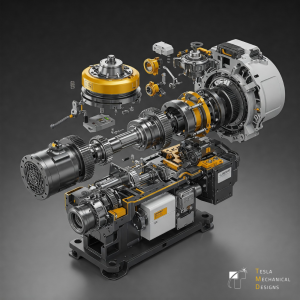

Mastering Complex Assemblies: Tesla Mechanical Design’s Expert CAD Team Tackles Challenging Engineering Projects

Tesla Mechanical Design: Experts in complex assembly design, from concept to manufacturing.

𝗧𝗵𝗲 𝗖𝗵𝗮𝗹𝗹𝗲𝗻𝗴𝗲 𝗼𝗳 𝗖𝗼𝗺𝗽𝗹𝗲𝘅𝗶𝘁𝘆

Modern engineering projects often involve intricate assemblies comprising numerous components with specifications and interdependencies. From aerospace components to intricate machinery and consumer electronics, the complexity of these assemblies poses significant challenges to design and manufacturing processes. These challenges include:

o Accurate Visualization and Interference Detection: Ensuring all components fit together seamlessly and function as intended requires sophisticated 3D modeling and visualization tools.

o Efficient Design Iteration and Modification: The ability to rapidly iterate on designs and incorporate changes is crucial for optimizing performance and meeting tight deadlines.

o Data Management and Collaboration: Managing large volumes of CAD data and facilitating collaboration among team members requires robust data management systems and workflows.

o Optimization for Manufacturing and Assembly: Designs must be optimized for manufacturability and ease of assembly to minimize costs and ensure quality.

"Our team's expertise in CAD and CAM allows us to tackle complex assemblies with confidence," said Kuldeep Gajjar, Director at Tesla Mechanical Designs. "By leveraging our expertise and cutting-edge CAD-CAM technologies we are able to create detailed 3D models, simulate real-world conditions through finite element analysis, and analyze design performance, ensuring that our clients receive robust and reliable solutions."

𝗧𝗲𝘀𝗹𝗮 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗗𝗲𝘀𝗶𝗴𝗻: 𝗔 𝗦𝗼𝗹𝘂𝘁𝗶𝗼𝗻 𝗣𝗿𝗼𝘃𝗶𝗱𝗲𝗿

Tesla Mechanical Design has established itself as a trusted partner for companies seeking to overcome these challenges. The company's expert CAD professionals deeply understand complex assembly design principles and have experience utilizing industry-leading software such as SolidWorks, AutoCAD, and other relevant CAD platforms/software.

𝗖𝗼𝗿𝗲 𝗖𝗼𝗺𝗽𝗲𝘁𝗲𝗻𝗰𝗶𝗲𝘀 𝗮𝗻𝗱 𝗦𝗲𝗿𝘃𝗶𝗰𝗲𝘀

o 3D Modeling and Assembly Design: Tesla Mechanical Design excels in creating detailed 3D models of complex assemblies, ensuring accurate representation of all components and their relationships.

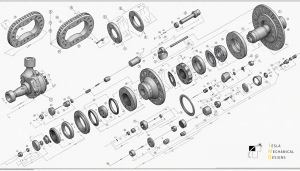

o Interference Detection and Clearance Analysis: The team performs thorough interference detection and clearance analysis to identify and resolve potential issues before manufacturing begins.

o Design Optimization and Simulation: Tesla Mechanical Design utilizes simulation tools to optimize designs for performance, manufacturability, and assembly, minimizing costs and maximizing efficiency.

o Bill of Materials (BOM) Management: The Company provides comprehensive BOM management services, ensuring accurate tracking of all components and their specifications.

o 2D Drafting and Technical Documentation: Tesla Mechanical Design offers detailed assembly drawing services and technical documentation for manufacturing and assembly purposes.

o Reverse Engineering: The business provides reverse engineering services, allowing for digitizing and modifying existing physical components.

o CAD Conversion and Migration: The Company offers CAD conversion and migration services, enabling seamless data transfer between different CAD platforms.

o Product Design and Development: Tesla Mechanical Design offers complete product design and development services, taking projects from concept to production.

o Mechanical Design Consultancy: The Company provides expert mechanical design consultancy services, assisting clients with all aspects of their engineering projects.

"Our experience in manufacturing gives us a unique advantage," said Kuldeep Gajjar. "We understand the intricacies of various manufacturing processes, allowing us to design components that are not only functional but also cost-effective to produce.

𝗞𝗲𝘆 𝗗𝗶𝗳𝗳𝗲𝗿𝗲𝗻𝘁𝗶𝗮𝘁𝗼𝗿𝘀

o Expert Team: Tesla Mechanical Design comprises highly skilled and experienced CAD professionals with a proven track record of success in complex assembly design.

o Advanced Technology: The company leverages the latest CAD software and hardware to ensure accuracy, efficiency, and seamless collaboration.

o Client-Centric Approach: Tesla Mechanical Design prioritizes client satisfaction. It works closely with clients to understand their specific needs and deliver tailored solutions.

o Commitment to Quality: The company applies stringent quality control measures to ensure all deliverables meet the highest standards.

o Versatility: Tesla Mechanical Design has experience in a wide variety of industries and can adapt to the needs of many different projects.

o Focus on Communication: Clear and consistent communication is maintained throughout the project lifecycle.

𝗖𝗮𝘀𝗲 𝗦𝘁𝘂𝗱𝗶𝗲𝘀 𝗮𝗻𝗱 𝗦𝘂𝗰𝗰𝗲𝘀𝘀 𝗦𝘁𝗼𝗿𝗶𝗲𝘀

Tesla Mechanical Design has a proven track record of delivering exceptional results on various challenging projects. Here are a few examples that highlight the team's expertise:

o Electronic and IOT Device Enclosures: Tesla Mechanical Design has extensive experience in designing, validating, and prototyping enclosures for various electronic and IOT devices. This includes designing enclosures using the optimal materials for the specific application, considering factors such as durability and stability. The team also provides post-delivery support for minor design and material changes and resolves any design errors identified in the final mechanical prototype. Prototype creation involves 3D printing for plastic enclosures and machining for sheet metal enclosures.

o Portable Car Charger Development: Tesla's Mechanical Design played a key role in the design validation and prototyping of the outer body of a portable car charger. This involved mounting all components inside the charger, providing necessary support, modifying the casing to meet IP65 rating standards, and creating the drawings for die design. The team also updated the design based on die designer/vendor suggestions and created white opaque 3D printed and vacuum-casted prototypes using PU-based material.

o Table-Top Injection Molding Machine: Tesla Mechanical Design took on designing and developing a table-top injection molding machine for manufacturing packaging goods. The design was required to be very compact (4 x 1.5 x 2.5 ft) for use in homes in rural areas. The machine was designed for easy die replacement and included a water-cooling system to regulate the die.

o Folding Metal Wire Frame with Hinges: Tesla Mechanical Design successfully designed, developed, and supported the mass manufacturing of a multifunctional hinge for collapsible utility tote bags. The project involved creating a hinge capable of collapsing and upholding a rectangular metal wire frame fixed to the open side of the tote bag. The hinge facilitates the folding and unfolding of the tote bag and can hold the bag open even with heavy objects (up to 30 kg) inside. The hinge had a maximum dimension of 25mm. Three designs were created, prototypes were developed, and the best-performing prototype was selected for mass manufacturing. Tesla Mechanical Design manufactured 20,000 pieces of the final hinge design and shipped them to the client overseas.

o EVAC 240kW Charger Support: Tesla Mechanical Design provided design validation of the cabinet and support during mass manufacturing and electromechanical assembly for a 240kW EVAC Charger. This included verification/modifications of parts for manufacturability, design structuring, parts interfacing verification, hardware optimization, 2D drawing preparation, support for cabinet manufacturing, and support for the production team during electromechanical assembly.

These case studies illustrate Tesla Mechanical Design's ability to handle diverse and complex projects, from initial concept and design to prototyping and manufacturing support.

𝗧𝗵𝗲 𝗧𝗲𝘀𝗹𝗮 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗗𝗲𝘀𝗶𝗴𝗻 𝗔𝗱𝘃𝗮𝗻𝘁𝗮𝗴𝗲

By partnering with Tesla Mechanical Design, clients gain access to a team of experts who can handle the most challenging complex assembly design projects. The company's comprehensive services, advanced technology, and client-centric approach ensure that projects are completed on time, within budget, and to the highest quality standards.

𝗟𝗼𝗼𝗸𝗶𝗻𝗴 𝗔𝗵𝗲𝗮𝗱

As technology advances and engineering projects become increasingly complex, Tesla Mechanical Design remains committed to staying at the forefront of the industry. The company is continuously investing in its team, technology, and processes to ensure that it can continue to provide its clients with the highest level of service and expertise.

"Cutting-Edge CAD technologies has become an indispensable tool for our engineering team," said Prex Poojara, Director at Tesla Mechanical Designs. "It allows us to visualize designs in 3D, simulate real-world conditions, and analyze design performance, enabling us to identify and address potential issues early in the design process."

𝗔𝗯𝗼𝘂𝘁 𝗧𝗲𝘀𝗹𝗮 𝗠𝗲𝗰𝗵𝗮𝗻𝗶𝗰𝗮𝗹 𝗗𝗲𝘀𝗶𝗴𝗻

Tesla Mechanical Design is a leading Engineering Design and Automation Company specializing in complex assembly design, 3D modeling, 2D drafting, and product development. With a team of highly skilled CAD professionals and a commitment to excellence, the company empowers clients across diverse industries to bring their most challenging engineering projects to fruition. Visit www.teslamechanicaldesigns.com for more information. Do you have a challenging engineering project? Contact us at info@teslamechanicaldesigns.com, and let us help you execute your project!

Divya Dave

Tesla Mechanical Designs

+1 214-699-6163

email us here

Visit us on social media:

LinkedIn

Other

Distribution channels: Business & Economy, Companies, Manufacturing, Technology, World & Regional

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release